“Preferable” is always a matter of subjective choice and knowing the options to choose from. In the world of cable assemblies and wire harnesses, there is a multitude of choices. Let’s simplify the choices to basic categories: LASER MARKING vs LABELING.

LASER MARKING or ETCHING current technologies offer a straightforward set of pro’s & con’s based on current technologies. However, labeling offers many options to be considered. Which is correct for your applications? The answer, as with most things, is “it depends”.

Let’s break it down in the straightforward discussion of the Pros & Con’s of each.

LABELING

PRE-PRINTED HEAT SHRINK, TAG or WRAP AROUND labels have been used for decades. Suffice to say there are as many product options as there are applications. Finding the correct one may take some time but once found a word of advice; be flexible on the end product’s documentation and note something like “ACME label, PN XXXXXX or equivalent with engineering approval”. Nothing slows up production faster than a contractor trying to source some obscure label that USED to be available but has fallen off and isn’t so ubiquitous as it USED to be. IPC/WHMA 620 is very flexible on this point as long as the correct information is legible and where it’s supposed to be.

PROS

- An incredible choice of options

- Print “on-demand” or pre-print large batch for lower cost

- Color printing is possible

- Options for bar-coding and more lines of data possible

CONS

- Sometimes can be torn off

- Consistency in location positioning can be an issue

- Removal if there is a quality issue is costly

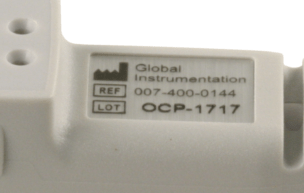

APPLIED LABEL

APPLIED LABEL

This is typically more for permanent labeling for of the yoke or larger over-molded area of a cable assembly. It is also commonly used on dongle cables with plastic case.

PROS

- An incredible choice of options

- Color printing is possible

- Barcoding common

- Graphics for company logo’s etc. have better resolution

CONS

- Print on demand not as common. Usually must be pre-printed.

- Consistency in location positioning can be an issue

- Removal if there is a quality issue is costly

LASER ETCHING

LASER ETCHING

Laser Etching is a permanent way to mark cable assemblies, bulk cable, and wire harnesses. As the cost and efficiency of the equipment have come down it has become more common for the marking bulk cable (UL #, temperature/voltage rating, etc.). However, now it is also becoming more common as a marking approach for cable assemblies.

PROS

- Permanent. Cannot be removed

- Can be high resolution for alphanumeric marking

- Barcoding possible

CONS

- Permanent. Cannot be removed. No second chances.

- Graphics are typically not as high resolution

- Barcoding possible but limited to non-QR options

LASER LABEL ON BULK CABLE OR FOIL/INKJET NUMBERING ON WIRE HARNESSES.

LASER LABEL ON BULK CABLE OR FOIL/INKJET NUMBERING ON WIRE HARNESSES.

This is common on bulk cable complex wire harnesses. On the bulk cable, there is no cost impact worth noting. However, on wire harnesses, this is a discrete and labor-intensive process particularly if there are multiples of identification numbers i.e. ID numbers on legs of a complex assembly. However, this could be well worth the cost in order to achieve clear marking on complicated assemblies with long distances between connection point.

Please feel free to comment or send your inquiry to sales@ocp.com or visit our website.